At our current stage we are scaling the working prototype to the designed parameters of production from 50 up to 70 tons of raw materials per hour so it can be widely used in the milling industry. This is our roadmap.

KELNIG Robo-Mill is a complex of several industrial functions: comminution of rock particles with hardness up to 9 Mohs, activation of those particles in-flow at speed 300 meters per second, homogenization of multicomponent mixtures, full separation of the product from the working zone, defined by top particle size scale, dehumidification by vortex flow at temperatures 120 degreed Celcius, transportation with the waste air flow at distances up to 150 meters.

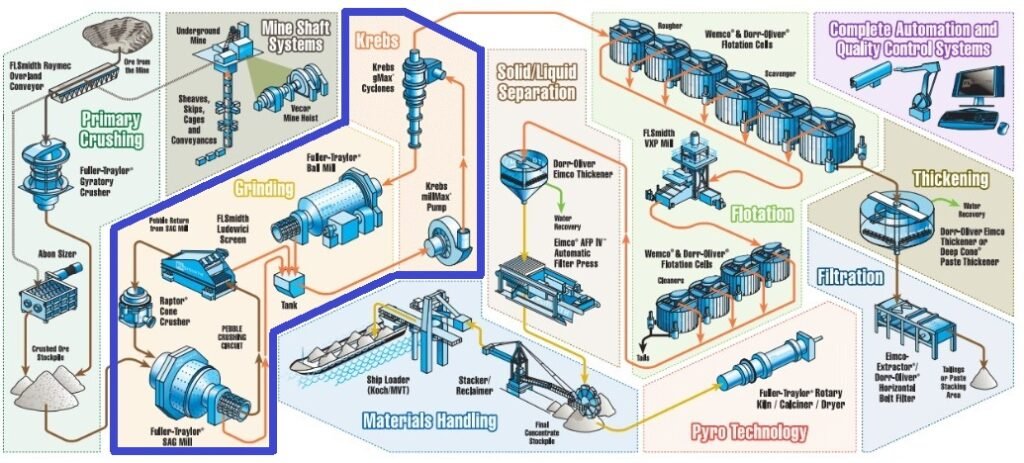

It can be easily integrated into the industrial chain of most of the milling complexes around the world and can replace these steps in the comminution cycle.

As of 2023, the volumetric demand for industrial minerals is projected to reach 2,377.7 million tons. This growth reflects a compounded annual growth rate (CAGR) of 2.8% from 2023 to 2030. The Mineral Processing Equipment Market was valued at USD 19.93 Billion in 2021 and is projected to grow to 27.48 billion by 2027, registering a CAGR of 5.5% in terms of revenue during the forecast period.

Due to the depletion of mineral ores concentration in raw materials, the cost of their extraction and milling is constantly rising, making it economically challenging to explore mines with lower concentration of mineral ores and its refining. Therefore, a significant amount of grand construction projects become unprofitable, potential of new materials creation is limited by the particles size, and the newer ones, like micro cement, are very expensive and slow in production.

Economic advantages of KELNIG Robo-Mill on the example of micro cement:

Cement clinker – $50 per ton.

Blast furnace slag – $50 per ton.

Grinding – $14 per ton.

Activation – $0 per ton.

Homogenization – $0 per ton.

Cement clinker and blast furnace slag is crushed to 5 microns with simultaneous activation and homogenization of particles.

The cost of production is $114 per ton.

Low cost allows you to influence the market.

The average market price of micro cement per ton is $1300

Characteristics of the KELNIG Robo-Mill:

Device type – centrifugal

Particle velocity – 300 m/s

Air flow rate – 11000 m³/h

Method of Technology – Gap

Energy consumption – 7 kWh/t

Capacity – from 50 t/h

Grinding media – No

Inert gases, reagents – No

Infrastructure – Not required

The weight of the device is 12 tons.